TEMC New Plant In Xuzhou, China Officially Put Into Production

To provide the most convenient service instantly,

TEMC has established the first oversea manufacturing base and get ready to take steps into the world.

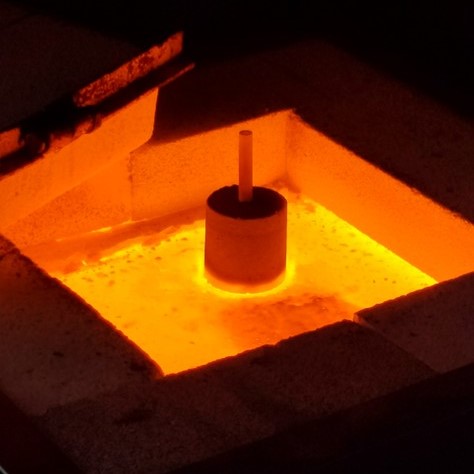

TEMC has always endeavor to improve the service quality and shorten the distance of supply chain, according to the marketing experience we had accumulated in Mainland China for almost two decades, and after we had made countless investigations and researches, TEMC has officially established our very first oversea manufacturing base in 2021, and formally start the producing line at July 2022. It is located in Tongshang district, Xuzhou, Jiangsu Province, a spectacular city that breeds Han culture. The base has a standardized workshop and office area of about 5,000 square meters, which is mainly used for the manufacture of riser sleeves, material testing, warehousing logistics and sales.

TEMC manufacturing base owns a great geographical advantage that is hardly to be replaced, it has occupied the main connecting spot of foundry industries clusters in the south, north and the central part, which will be fully capable of supporting the transportations to Shandong, Jiangsu, Anhui and Hainan and even the whole of China, it will greatly enhance the customer service experience. It is about 200 kilometers away from the port, which will also provide great convenience for the export of products in the future. The base has set up four riser sleeve forming production lines and two drying lines, which ensures TEMC riser production take a qualitative leap. The standardized material laboratory with complete norm can certainly reach the high standard that TEMC has always pursued for product quality; In terms of material using, the selection of recycled and environmentally friendly materials such as soluble environmentally friendly fibers has laid a foundation for the establishment of green modern factories and in response to the country’s efforts to promote circular economy.

TEMC adheres to the company’s vision of “MAKE FOUNDRY CLEAN, AND HAPPY WORK “, and will continue to expand product lines and develop new green foundry materials in the future to better provide foundries high-quality products and professional service solutions.