GREEN FOUNDRY GREEN MANUFACTURING SEMINAR

TEMC hosted the first GREEN FOUNDRY GREEN MANUFACTURING SEMINAR at TEMC’s Green Foundry Technology Center on 11th March, 2021. This is one of a series of foundry technology seminars TEMC presents to Taiwan foundry industry. Of this seminar, a few topics including 1) Sand mold quality management, 2) How to apply SOLIDCast on green foundry? 3) TCaST-3D sand mold printing technology, 4) Foundry new technology & new knowledge.

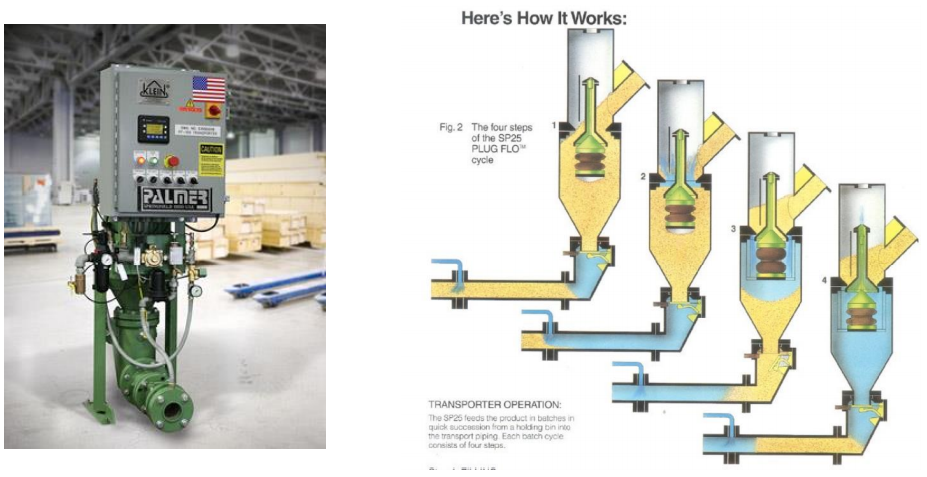

First talk was given by Dr. S-C Huang from TEMC, he explained the importance of sand key factors, such as grain distribution, sand roundness, and sand purity, on sand mold quality management. High-efficient mixer plays a key role for sand mold quality, especially when applying smart pumping system on sand mold manufacturing process. With low-pressure pneumatic sand transporter, and HCCL sand fluidization bed to control sand dust amount in sand system to own high sand quality. High sand mold quality leads to great casting quality, also eliminates excess production cost, and further reduces waste disposal.

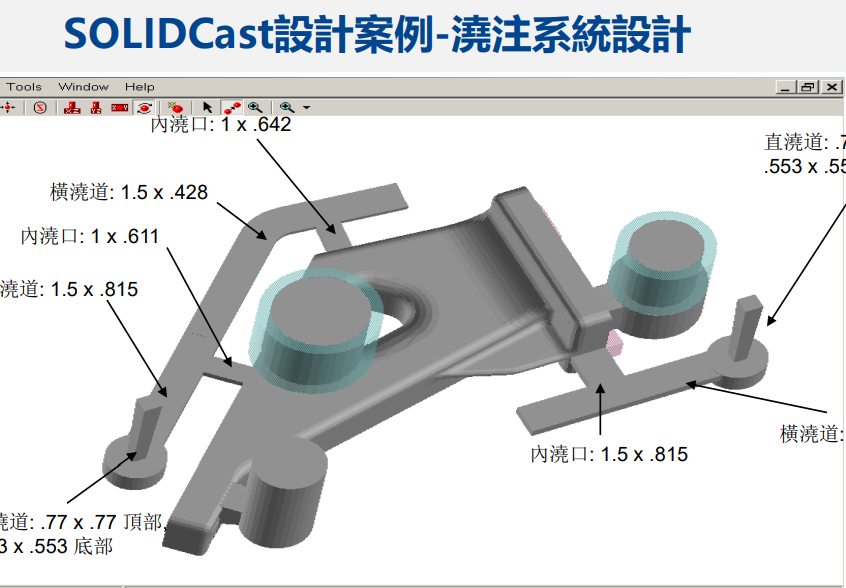

Second topic was contributed by SOLIDCast Engineer, Mr. C-W Hsu from TEMC who showed casting pouring and solidification simulations from naked casting status. Further Optimization calculation results were presented to show how to lower gating system design time cost. Higher yield rate means lower pouring energy is needed to achieve green found manufacturing purpose.

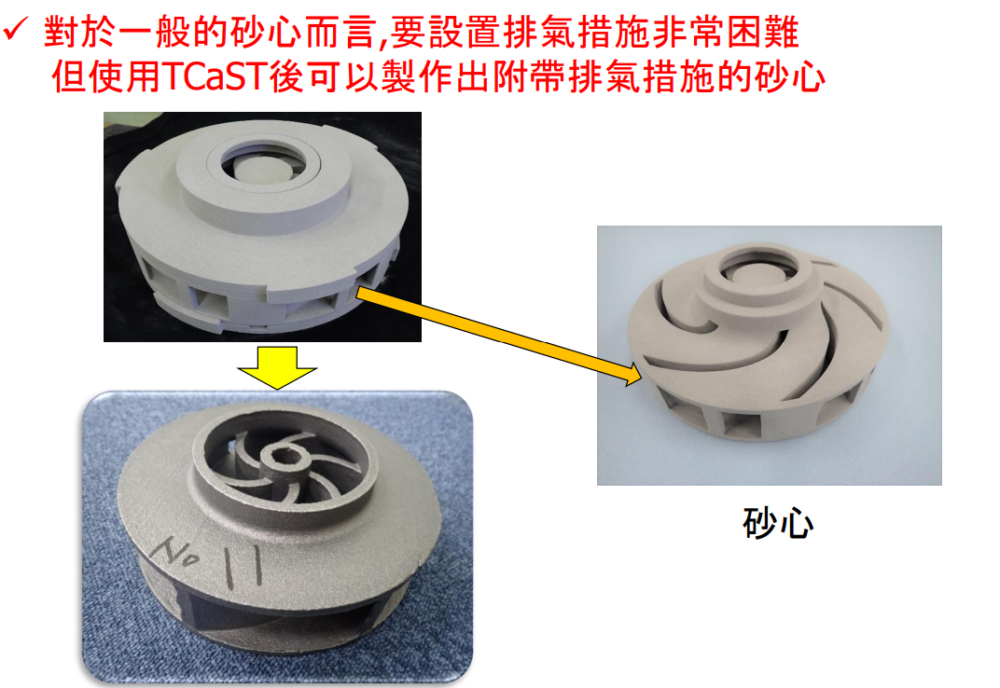

Third topic was presented by an on-line speaker Mr. Toshinori Kanemitsu from Taiheiyo Cement, Japan, to show 3D sand mold trends in nowadays. It uses a binder jet 3D printer developed by 3D system company to form sand molds. It significantly shortens sand mold preparation time even with a complex mold structure. Fine sand mold surface also reflects on its fine casting surface details. 3D sand molds apply on a variety of materials, from aluminum to steel castings.

Final talk was given by Prof. Y-N Pan from National Taiwan University who delivered information of development trends of casting alloy materials, molding machine, and casting manufacturing methods. By joint with further few topics, he recommended that Taiwan foundry industry embarks to wind mill turbine fields (green energy), bio-medical fields (dental and artificial joint material developments), aero-space industry and military defense field.

Green foundry manufacturing is a global development trend, TEMC as the leading role of Taiwan foundry material industry, it is our obligation to lead Taiwan foundries to meet the goal. TEMC aims to promote the progress of green foundry manufacturing in Taiwan by hosting this seminar.